Nowadays, traditional air cooling has reached the ceiling. Whether it is cutting-edge GPUs driving AI models or high-density servers carrying data torrents, their huge thermal power consumption calls for more efficient and precise cooling solutions.

Why shovel tooth technology? The skiving process uses ultra-high-precision cutting to "carve" an intricate internal micro-channel structure with ultra-thin fins from a complete metal substrate. This is not only an innovation in manufacturing methods, but also a qualitative change in heat dissipation performance:

Characteristic dimension: traditional copper tube/brazed cold plate, shovel tooth process liquid cooling plate/water-cooled head.

Heat transfer path and efficiency: There are multi-layer material interfaces (copper tube-fin-base), and the contact thermal resistance is large. The fins and base are 100% integrated, with zero contact thermal resistance and maximum heat conduction efficiency. Directly lowers the chip junction temperature, ensures continuous high-frequency operation of the hardware, and improves computing stability and lifespan.

Microchannel design: The channel size is limited, the hydraulic diameter is large, and it is difficult to achieve both flow resistance and heat transfer efficiency. Ultra-thin and ultra-high-density microchannels can be customized (tooth thickness can be <0.3mm), which greatly increases the heat exchange area and achieves efficient turbulent flow. Obtain higher heat dissipation performance under the same pump power; or reduce cooling system energy consumption under the same heat dissipation demand.

Reliability: There is a risk of solder fatigue and thermal stress failure between copper tubes and fins. The one-piece metal structure with no welds or interfaces completely eliminates the risk of leakage and is highly resistant to pressure and corrosion. Meet the stringent requirements of 24x7 uninterrupted operation and provide ultimate reliability for data centers and supercomputers.

Customization flexibility: The mold opening cost is extremely high, design changes are difficult, and the cycle is long. No mold is required, and customization can be quickly responded to customer chip size, heat source distribution, and interface location. Perfectly adapted to NVIDIA GB200/GB300 and other non-public versions or self-developed chips, achieving "tailor-made" precise heat dissipation.

Product series core introduction

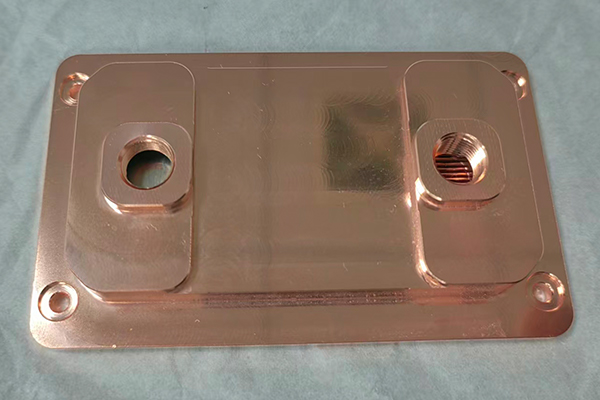

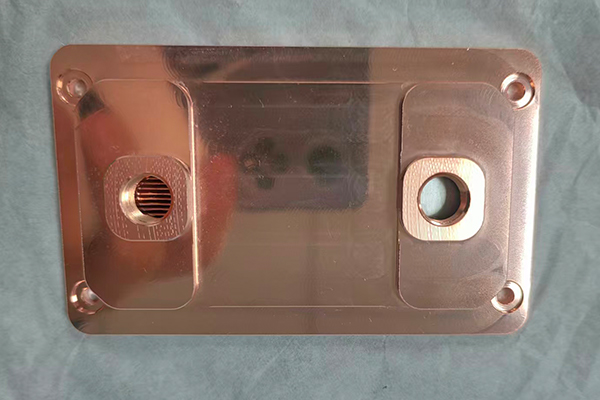

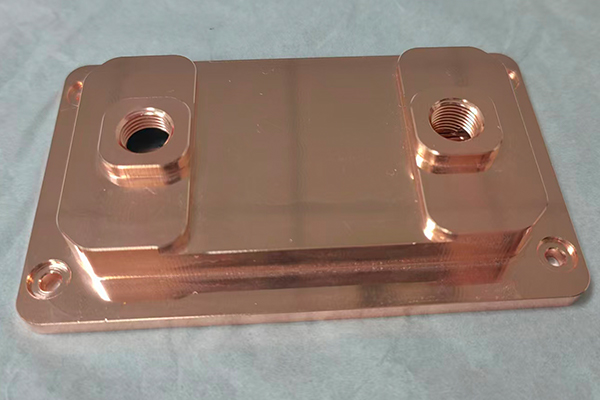

1. Shovel-tooth CPU/GPU integrated water block

Design: Targeted at high-performance desktop workstations, high-end gaming PCs and single-channel AI servers. The pure copper shovel tooth micro-channel heat absorption base covers the entire chip and surrounding high power consumption areas. Compatible with mainstream buckles, pre-installed with high-quality interfaces and leak-proof quick-twist.

Core advantages: Compared with cast cold heads, the heat exchange efficiency is significantly improved, which can instantly suppress the surge in instantaneous power consumption of the CPU/GPU, providing overclocking players and professional creators with surging and stable performance output.

2. Shovel-tooth server liquid cooling plate

Design: Specifically designed for data center GPU accelerator cards (such as NVIDIA SXM series), high-performance computing CPUs and high-power ASIC chips. Fully customized development can be carried out according to the chip layout, thermal design power (TDP) and system flow resistance requirements provided by OEM/ODM customers.

Core advantages: The integrated shovel tooth structure ensures maximum heat dissipation capacity in a limited space. It is a core and reliable component for building direct-to-chip data centers and immersed liquid cooling clusters.

3. Complex flow channel shovel tooth cold plate

Design: Complex internal flow channels in parallel or series can be designed for multiple chips (such as CPU+GPU+VRAM cluster) to achieve intelligent matching of flow and heat load and optimize the overall energy efficiency of the system.

Core advantage: Solve the problem of heat dissipation with multiple heat sources and non-uniform heating